Table of Contents

ToggleEngineered Wood vs Plywood: The Real Debate for Delhi NCR

The engineered wood vs. plywood debate is no longer just about looks—it’s about ROI, sustainability, and the speed of construction.

In the Delhi NCR region, where temperatures fluctuate from 4°C in January to 48°C in June (IMD Delhi Temperature Report), choosing between engineered wood vs plywood can make or break your project. Even a minor material mismatch can cause cracks, swelling, or veneer peel-offs within months.

That’s why construction companies like Hindpride are leading the shift from generic “wood choices” to spec-driven material engineering—helping builders understand the engineered wood vs plywood equation clearly.

When comparing engineered wood vs plywood, engineered wood is an umbrella term for wood-based composites made from fibres, strands, or veneers bonded together with heat-cured adhesives under pressure.

According to the Forest Research Institute, Dehradun, engineered wood now accounts for nearly 45% of interior-grade panel production in India—a key factor in the shift from plywood to engineered wood in the market.

Key Types Used in NCR Interiors

💡 Sustainability Note:

According to PEFC India, each cubic metre of engineered wood saves up to 1.2 tonnes of CO₂ emissions compared to solid hardwood—a crucial advantage in the engineered timber versus plywood sustainability debate.

In the engineered wood vs plywood comparison, plywood is a classic, time-tested product made by cross-bonding thin wood veneers. Each veneer layer runs perpendicular to the previous, providing strength, rigidity, and dimensional stability.

| Grade | IS Code | Bond Type | Recommended Use |

|---|---|---|---|

| MR (Moisture Resistant) | IS 303 | Urea-formaldehyde | Interiors, dry zones |

| BWR (Boiling Water Reactor) | IS 303 | Phenol-formaldehyde | Kitchens, bathrooms |

| BWP (Boiling Water Proof) | IS 710 | Phenol-formaldehyde | Heavy-duty wet use |

| Marine Plywood | IS 710 | Phenolic resin | Exteriors, boats, labs |

Understanding these grades is essential when evaluating engineered wood vs plywood for your specific project needs.

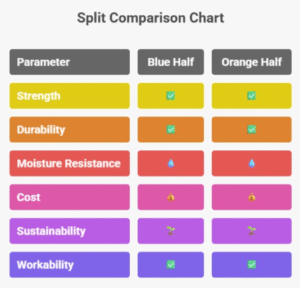

The engineered wood vs plywood performance comparison becomes critical under Delhi NCR’s climate stress test—alternating between dry heat and high humidity.

The Central Building Research Institute (CBRI) tested both materials in the engineered wood vs plywood study:

| Parameter | Engineered Wood | Plywood | Winner in Engineered Wood vs Plywood |

|---|---|---|---|

| Swelling After 24h Soak | 8–12% | 2–4% | ✅ Plywood |

| Screw Withdrawal Strength | 600–700 N | 900–1200 N | ✅ Plywood |

| Dimensional Change (RH 85%) | Moderate | Low | ✅ Plywood |

| Fire Resistance | Low | Moderate | Tie |

| Formaldehyde Emission (mg/L) | 0.5–1.2 | 1.0–1.5 | ✅ Engineered Wood (E1 grade) |

In the engineered wood vs plywood longevity comparison:

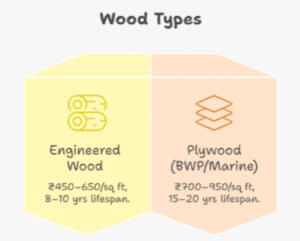

Average lifespan (Delhi NCR commercial use):

Routine maintenance tips (as per Asian Paints Wood Finishes Guide):

Pro Insight: Hindpride’s Modular Office Pods (2024–25) utilised laminated MDF, demonstrating smart engineered wood vs plywood selection that saved 18% in material and 22% in installation time.

The engineered wood vs plywood cost analysis, sourced from Indiamart, JustDial, and ContractorBhai:

| Material | Thickness | Rate (₹/sq ft) | Installation | Finish Type |

|---|---|---|---|---|

| MDF (E1 grade) | 18 mm | 55–65 | +20 | Laminate/PU |

| HDF | 18 mm | 75–85 | +25 | PU |

| Particle Board | 18 mm | 35–45 | +15 | Matte |

| BWR Ply | 18 mm | 100–120 | +30 | Laminate |

| BWP Ply | 18 mm | 130–160 | +35 | PU/Veneer |

| Marine Ply | 18 mm | 160–180 | +40 | Veneer |

Engineered wood vs plywood total project cost: Engineered wood ≈ ₹450–₹650/sq ft vs Plywood ≈ ₹700–₹950/sq ft (Housing.com Cost Calculator).

| Property | Engineered Wood | Plywood | Engineered Wood vs Plywood Winner |

|---|---|---|---|

| Machinability | Excellent (CNC-friendly) | Moderate | Engineered Wood |

| Bending Strength | 20–25 MPa | 30–35 MPa | Plywood |

| Edge Stability | Needs sealing | Stable | Plywood |

| Finish Absorption | Excellent | Good | Engineered Wood |

| Weight | 600–800 kg/m³ | 700–900 kg/m³ | Engineered Wood (lighter) |

In the engineered wood vs. plywood workability test, modular carpenters prefer MDF for CNC cutting precision, which is ideal for perforated acoustic panels.

India’s green building sector is projected to reach $80 billion by 2030 (IGBC Annual Report 2024), making the engineered wood vs plywood sustainability factor crucial.

Engineered wood advantages in engineered wood vs plywood:

Plywood eco-innovation in engineered wood vs plywood:

🟩 Tip: Ask vendors for FSC Chain-of-Custody certificates (FSC Verification Portal)—a key factor in the engineered wood vs plywood LEED/IGBC points equation.

Both materials in the engineered wood vs plywood comparison adapt beautifully to modern NCR design:

For high-traffic zones, Hindpride recommends 0.8mm laminate over MDF or plywood, backed by an anti-scratch PU coating (Asian Paints Touchwood Guide)—solving the dilemma between engineered wood and plywood finishes.

When deciding between engineered wood vs plywood:

Critical errors in the engineered wood vs plywood installation:

Hindpride mandates a 4-step QC checklist derived from CPWD Woodwork Specifications for every engineered wood vs plywood project.

So, engineered wood vs plywood—which wins?

💬 Final Word from Hindpride’s Technical Head:

“At Hindpride, we don’t pick sides in engineered wood vs plywood. We use plywood for strength, engineered wood for scale. The smartest builds are hybrids.”

1. In engineered wood vs plywood, which lasts longer in humid areas?

Plywood—especially Marine or BWP grades (BIS IS 710 Standard)

2. Can engineered wood be used in bathrooms in the engineered wood vs plywood choice?

Not directly. Use moisture-resistant MDF with PVC lamination (Action TESA Aqua+ Boards)

3. In engineered wood vs plywood, what’s safer for indoor air quality?

E0/E1 engineered wood emits less formaldehyde (CPCB VOC Report 2023)

4. Engineered wood vs plywood: which is more sustainable?

Engineered wood, due to efficient timber use (FAO Report 2024)

5. What’s the cost difference in the engineered wood vs plywood comparison for Delhi NCR?

Average 30–35% cheaper to start (Housing.com Cost Tool)

Every square foot you design is an investment—and choosing between engineered wood and plywood correctly can significantly extend your project’s lifespan, enhance its aesthetics, and increase its resale value.

Whether you’re crafting modular offices, farmhouses, or commercial complexes in Delhi NCR, the Hindpride team combines 30 years of construction experience with cutting-edge modular innovation to solve your engineered wood vs plywood challenge.

✅ Material Expertise — Our engineers evaluate the engineered wood vs plywood equation per the IS code and site conditions

✅ Faster Project Timelines — Modular integration reduces delivery by up to 31%

✅ Sustainability First — IGBC-aligned specifications and FSC-certified materials

✅ Cost Transparency — Data-driven budgeting and procurement dashboards

✅ Post-Completion Support — Maintenance, lifecycle tracking, and retrofit options

Ready to Settle the Engineered Wood vs Plywood Debate for Your Project?

📞 Book Your Free Material Consultation

Our experts will analyse your site, budget, and timeline—and deliver a custom 2025 Specification Report that solves your engineered wood vs plywood challenge within 24 hours.

🔗 Schedule a Consultation → Hindpride.com/contact

✉️ Email: connect@hindpride.com

📍 Service Areas: Delhi, Gurugram, Noida, Faridabad, Ghaziabad

Hindpride Modular Construction — Building Smarter, Faster, and Greener for Tomorrow’s India.