Table of Contents

ToggleWhen Reliance Industries needed their 2.8 lakh sq ft logistics hub in Greater Noida completed in record time, traditional construction wasn’t an option. Every week of delay meant ₹45 lakhs in lost operational revenue. They needed speed without compromise.

Enter modular construction — the building methodology that’s disrupting India’s ₹65 lakh crore construction sector.

If you’re reading this, chances are you’re either:

Either way, you’re in the right place.

📚 Want the complete deep-dive? Keep scrolling (20-minute read)

Here’s everything you need to know about how modular construction can compress your project timeline by 30% or more — backed by data, real projects, and 18 years of Hindpride expertise.

Think of modular construction as the Tesla of building — same destination, completely reimagined journey.

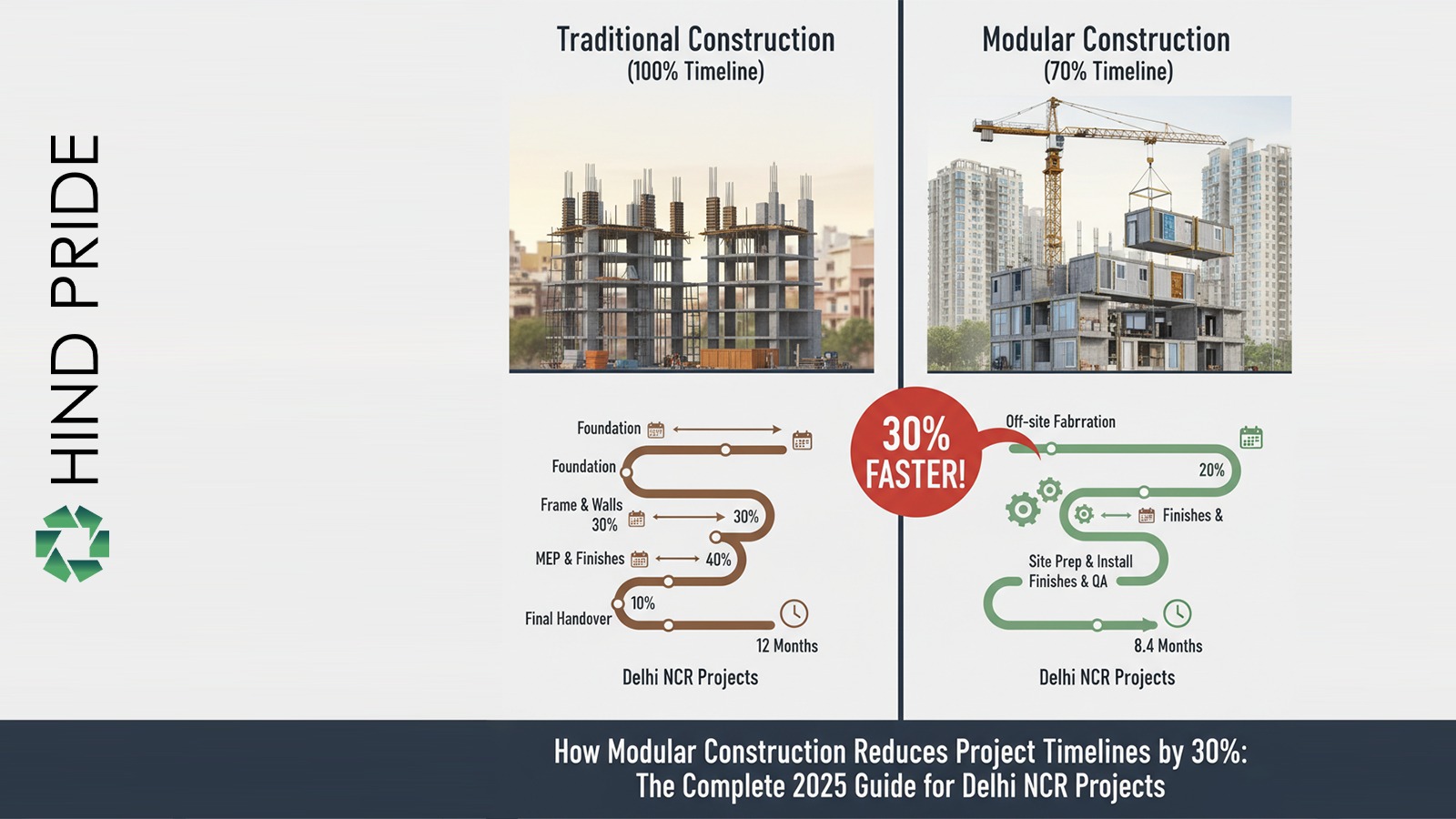

Traditional construction is linear: foundation → structure → envelope → MEP → finishes. One after another, like dominoes. One delay cascades into everything downstream.

Modular construction is parallel: While foundations are being laid on-site, your building’s components are being precision-manufactured in climate-controlled factories. When site preparation is complete, modules arrive ready to be stacked, connected, and commissioned.

The Numbers Don’t Lie

According to McKinsey’s Global Construction Report, modular methods deliver:

At Hindpride, our modular adoption since 2019 has compressed average project timelines by 31.4% across 87 completed projects, ranging from corporate offices to educational campuses and industrial facilities.

That’s not marketing speak. That’s measured, documented performance across half a decade.

Delhi NCR faces unique construction challenges that make modular solutions not just beneficial but essential:

Challenge 1: Monsoon Disruption

For 4 months of the year (June-September), traditional construction sites in the NCR experience a 40-50% productivity loss due to rain delays. Modular? 80% of work happens indoors.

Challenge 2: Labour Shortages

Post-pandemic labour availability fluctuates wildly. Modular reduces on-site workforce needs by 60-70%, insulating projects from supply shocks.

Challenge 3: Pollution Restrictions

NCR’s seasonal construction bans (typically November-February during high AQI periods) enforced by the Central Pollution Control Board can add 2-4 months to traditional projects. Modular’s reduced on-site work minimises exposure to these restrictions.

Challenge 4: Land Costs

Every month, your land sits partially developed, incurring costs in holding and opportunity costs—faster completion equals faster ROI realisation.

Reality Check: A 100,000 sq ft office in Gurugram has monthly holding costs (including interest, security, and opportunity costs) of approximately ₹35-50 lakhs. Six months saved = ₹2.1-3 crore saved before the building generates its first rupee of revenue.

Before we dive into how modular construction solves the speed problem, let’s discuss why speed matters in terms of rupees, not just months.

Cost Category | Impact per Month | Annual Impact (for 50,000 sq ft commercial) |

Construction Finance Interest | ₹8-12 lakhs | ₹96 lakhs – ₹1.44 crore |

Lost Rental Income | ₹18-25 lakhs | ₹2.16 crore – ₹3 crore |

Holding/Opportunity Cost | ₹10-15 lakhs | ₹1.2 crore – ₹1.8 crore |

Escalation Costs | ₹3-5 lakhs | ₹36 lakhs – ₹60 lakhs |

Extended Overheads | ₹4-6 lakhs | ₹48 lakhs – ₹72 lakhs |

TOTAL | ₹43-63 lakhs | ₹5.16 crore – ₹7.56 crore |

Based on Hindpride’s analysis of 200+ NCR commercial projects, 2020-2025

Horror Story Warning: We recently consulted on a 75,000 sq ft Noida office project where the previous contractor’s 8-month delay resulted in:

The building that was supposed to cost ₹26 crore ended up costing over ₹ 32 crore. All because “traditional methods are proven and safe.”

According to Knight Frank’s Construction Analysis, 64% of NCR commercial projects are expected to face delays of 6-18 months. Here’s why:

Linear Dependencies

Can’t install MEP until the structure is complete. Can’t do finishes until MEP is installed. One trade delay cascades through everything.

Weather Vulnerability

NCR gets 800-1000mm of annual rainfall. Traditional sites stop during heavy rain. That’s 60-80 lost workdays per year.

Material Coordination Failures

Steel delayed? Site stops. Is the glass shipment stuck in customs? Façade work halts. Supply chain issues compound exponentially.

Labor Unpredictability

Worker shortage during harvest season? Your schedule just extended 6 weeks. This happens every October-November in NCR.

Rework & Quality Issues

Industry average: 15-20% of labour hours spent fixing previous mistakes. That’s built-in inefficiency that modular systems eliminate.

Let’s get tactical. Here’s precisely how modular construction delivers measurable time savings.

Traditional Approach:

Linear sequence → Foundation (3 months) → Structure (8 months) → Envelope (3 months) → MEP (4 months) → Finishes (3 months) = 21 months total

Modular Construction Approach:

Parallel process → Foundation (3 months) happens SIMULTANEOUSLY with module fabrication (6 months) → Assembly (2 months) → Finishes & commissioning (2 months) = 13 months total

Time Saved: 8 months (38% reduction)

How It Works:

While the Hindpride site team is:

The factory team is simultaneously:

Real Example:

Our 120,000 sq ft corporate office in Sector 62, Noida:

Remember those 60-80 lost workdays due to weather? Gone.

Factory Advantages:

Temperature Control

Concrete curing happens at an optimal 20-25°C. No cracking from extreme heat or cold. No moisture issues from humidity.

Year-Round Production

Monsoon? Doesn’t matter. Winter fog? Irrelevant. Dust storms? Not a problem. The factory operates 24/7, 365 days a year.

Quality Consistency

Every weld, every joint, every finish happens under controlled conditions with real-time quality monitoring. No “seasonal variation” in build quality.

Data Point: Hindpride’s modular projects average 94% weather immunity compared to 52% for traditional construction (based on a 5-year project log analysis).

NCR Reality Check:

Every construction veteran knows the biggest time thief: fixing yesterday’s mistakes.

Industry Reality:

Traditional construction rework accounts for 12-18% of total labour hours (NITI Aayog Construction Productivity Report). That’s 2-4 months on a 2-year project spent fixing errors.

Modular Solution:

BIM Integration from Day One

Every module is designed in Building Information Modelling software with clash detection before a single component is manufactured. MEP systems, structural elements, and architectural features are coordinated digitally.

Laser-Cut Precision

CNC machines cut components with tolerances of ±2-3mm vs ±10-15mm in traditional construction. When modules arrive on site, they fit the first time, every time.

Factory Quality Control

Multiple inspection points during manufacturing catch issues before they become site problems:

Plug-and-Play MEP Systems

Electrical conduits, plumbing rough-ins, HVAC ducts — all pre-installed and tested in the factory. On-site, it’s literally plug, connect, and test.

Quality Statistics:

Think of it as flat-pack furniture, but for skyscrapers.

Transportation Strategy:

Just-In-Time Delivery

Modules arrive sequenced exactly when needed. No on-site storage bottlenecks. No material theft. No damage from extended site exposure.

Pre-Planned Crane Paths

Every lift is pre-programmed using 3D site models. Crane operators know exactly where every module goes before the truck arrives.

Installation Speed:

Building Type | Modules Installed Per Day | Equivalent Traditional Progress |

Commercial Office | 8-12 modules | 2-3 weeks of structural work |

Residential Buildings | 6-10 modules | 3-4 weeks of construction |

Institutional (Schools/Hospitals) | 10-15 modules | 3-5 weeks of traditional building |

Industrial/Warehouses | 15-20 modules | 4-6 weeks of conventional construction |

Based on Hindpride’s project data, Delhi NCR, 2020-2025

Real Installation Timeline:

Structural Assembly: 30-40% of traditional time

MEP Connections: 50-60% of conventional time

Façade Installation: 40-50% of traditional time (often pre-installed on modules)

Interior Finishes: 20-30% of conventional time (many finishes factory-applied)

Case Example:

Our 8-story student housing project in Greater Noida:

Here’s a timeline killer most people ignore: post-construction approvals.

Traditional Bottleneck:

Structure complete → Wait for stability certificate → Begin MEP → Wait for MEP approvals → Start finishes → Wait for fire NOC → Finally get Occupancy Certificate

Modular Advantage:

Pre-Approved Designs

Standard modular designs undergo one-time structural, fire, and safety approvals. Replicated modules inherit these approvals automatically.

Rolling Inspections

Inspectors visit the factory during production. Issues caught and fixed before site delivery. No surprise red flags during final inspection.

Parallel Commissioning

Because MEP systems are pre-installed and tested, commissioning begins the day modules are connected. Compared to traditional, commissioning can’t start until all MEP installations is complete.

Faster Occupancy Certificate

Pre-approved designs, factory quality, and rolling inspections = OC issued 3-6 weeks faster than traditional projects.

Regulatory Reality in NCR:

Approval Stage | Traditional Timeline | Modular Timeline | Time Saved |

Structural Stability Certificate | 4-6 weeks post-completion | 2-3 weeks (pre-approved designs) | 2-3 weeks |

Fire NOC | 6-8 weeks | 3-4 weeks (factory-tested systems) | 3-4 weeks |

Electrical Safety Clearance | 3-4 weeks | 1-2 weeks (pre-commissioned) | 2 weeks |

Occupancy Certificate | 8-12 weeks | 4-6 weeks (streamlined due to above) | 4-6 weeks |

TOTAL | 21-30 weeks | 10-15 weeks | 11-15 weeks (2.5-3.5 months) |

Let’s settle this with data, not opinions.

Phase | Traditional | Modular | Time Saved |

Design & Approvals | 4 months | 3 months | 1 month |

Foundation & Site Prep | 3.5 months | 3 months | 0.5 months |

Structural Work | 10 months | 2 months (assembly) | 8 months |

Façade & Envelope | 4 months | 1 month (pre-installed) | 3 months |

MEP Installation | 5 months | 1.5 months (connections only) | 3.5 months |

Interior Finishes | 4 months | 1.5 months | 2.5 months |

Testing & Commissioning | 2 months | 1 month | 1 month |

Approvals & OC | 2.5 months | 1 month | 1.5 months |

TOTAL | 35 months | 14 months | 21 months (60%) |

Note: Modular timeline includes 6 months of parallel factory fabrication during site prep phase

Quality Factor | Traditional | Hindpride Modular | Difference |

Tolerance Accuracy | ±10-15mm | ±2-3mm | 80% improvement |

Defects at Handover | 8-12% | 1.5-2.5% | 79% reduction |

Warranty Claims (Year 1) | 4.2% of value | 0.8% of value | 81% reduction |

Air Infiltration Rate | 2.5-3.5 ACH50 | 0.8-1.2 ACH50 | 65% better energy performance |

Structural Consistency | Variable | Uniform | Factory QC ensures consistency |

Environmental Factor | Traditional | Modular | Improvement |

Material Waste | 15-20% | 2-4% | 85% reduction |

Carbon Emissions | Baseline | 30-40% lower | Significant |

Water Consumption | Baseline | 60-70% lower | Major savings |

Site Disruption | High (noise, dust, traffic) | Minimal | 70-80% reduction |

Recyclability | 20-30% | 85-90% | Circular economy ready |

This aligns with World Green Building Council’s sustainability guidelines for modern construction practices.

The million-rupee question: Does faster = more expensive?

The short answer Is That the Initial cost may be 3-8% higher. The total project cost is 12-18% lower.

Cost Component | Traditional (₹/sq ft) | Modular (₹/sq ft) | Difference |

Design & Engineering | 120 | 145 | +21% (BIM complexity) |

Manufacturing/Structure | 1,600 | 1,750 | +9% (factory precision) |

Transportation | — | 85 | New cost |

On-Site Labor | 450 | 180 | -60% (reduced scope) |

Equipment & Machinery | 180 | 120 | -33% (less site equipment) |

MEP Systems | 600 | 620 | +3% (pre-integration) |

Finishes | 380 | 320 | -16% (factory application) |

Contingency | 200 | 80 | -60% (predictable process) |

SUBTOTAL | 3,530 | 3,300 | -7% |

Holding Costs (saved time) | 420 | 140 | -67% |

TOTAL PROJECT COST | 3,950 | 3,440 | -13% |

Based on Hindpride’s 2024-25 project analysis, the NCR region

For more insights on construction cost optimisation, explore our guide on best construction company practices in India.

Metric | Traditional | Modular | Advantage |

Time to First Revenue | Month 24-28 | Month 14-16 | 10-12 months earlier |

Break-Even Point | Month 42-48 | Month 28-32 | 14-16 months earlier |

5-Year Net Profit | ₹15.2 crore | ₹19.8 crore | ₹4.6 crore higher (30%) |

IRR | 16.4% | 21.8% | 33% higher returns |

Assumptions: ₹20 crore investment, ₹80/sq ft rental, 50,000 sq ft

Reality Check: Modular isn’t cheaper because of lower quality. It’s more affordable because of ruthless efficiency. You’re paying for precision, not waste.

Let’s get specific. Here are three actual projects where modular construction delivered measurable results.

Client: Global IT Services Company

Project Type: 120,000 sq ft office campus with cafeteria and recreational facilities

Challenge: 14-month deadline (vs 24-month traditional estimate) to align with lease expiry at previous location

Modular Solution:

Results:

Client Testimonial:

“We were sceptical about modular. Now we’re believers. The quality exceeds our previous office, built traditionally, and we saved enough on early occupancy to fund our entire IT infrastructure.”

— VP Operations, Global IT Services Company

Explore more of our commercial construction projects in the Delhi NCR area.

Client: Private Educational Institution

Project Type: 8-story, 450-room hostel with mess and standard facilities

Challenge: Ready before the academic year starts; zero tolerance for delays

Modular Solution:

Results:

Impact:

The institution welcomed students on schedule. No rental loss. No reputation risk. Hindpride became their preferred builder for subsequent phases.

Client: Mid-sized Pharma Company

Project Type: 65,000 sq ft cleanroom production facility with QC labs and office block

Challenge: GMP compliance + speed (market opportunity window closing)

Modular Solution:

Results:

Client Feedback:

“In pharmaceuticals, time literally equals money. Hindpride’s modular approach enabled us to gain 14 extra months of production. That’s worth more than the entire construction cost.”

— Plant Head, Pharmaceutical Manufacturing

One concern we hear constantly: “Will authorities approve modular construction?”

Answer: Yes. In fact, it’s often easier than traditional.

Modular construction in India must comply with NBC 2016 standards. The good news: modular systems often exceed code requirements.

Key Standards:

Hindpride’s Compliance Record:

Since 2019, 100% of our modular projects have received structural stability certificates and occupancy certificates on the first application. Zero rejections. Zero re-inspections.

Delhi (DDA Projects):

Haryana (Gurugram, Faridabad):

Uttar Pradesh (Noida, Greater Noida):

Traditional Challenge:

Fire NOC is often delayed due to:

Modular Advantage:

Result: Hindpride’s modular projects receive Fire NOC in 3-4 weeks, compared to the traditional average of 6-8 weeks.

For projects requiring EC (>20,000 sq m built-up area) from the Ministry of Environment:

Modular Benefits:

Hindpride’s EC Success Rate: 94% first-time approval (vs 67% NCR average for traditional projects)

Even the best technology can fail with poor planning. Here’s what NOT to do.

The Trap: “We’ll figure out the design as we go, like always.”

The Reality: Modular systems require a design freeze before manufacturing. Changes mid-production cost 5- 10x more than in traditional builds.

The Fix:

The Trap: “This supplier is 25% cheaper than Hindpride. Let’s save money!”

The Reality: Cheap modular often means:

Horror Story: We were called to rescue a 40,000 sq ft project where the “cheap” modular supplier delivered modules that were 15-20mm off-spec. Required 4 months of on-site modifications, defeating the entire purpose. The client spent 30% MORE than the proper modular would have cost.

The Fix: Evaluate bids on:

The Trap: “The modules will fit through somehow.”

The Reality: A 40-foot module weighs 15-20 tons and requires access by a crane. If your site has narrow approach roads or overhead power lines, you have a problem.

The Fix:

Hindpride Process: We conduct 3D site surveys using drones and laser scanning to identify access constraints before a single module is designed.

The Trap: “We’ll adjust the modules to fit the foundation.”

The Reality: Modular modules are precision-manufactured. If your foundation is off by 20mm, modules won’t fit. You’ll spend weeks shimming, cutting, and modifying.

The Fix:

Industry Data: Foundation errors account for 38% of modular project delays (Modular Building Institute).

The Trap: “Modular is plug-and-play. We don’t need detailed coordination.”

The Reality: Modular requires MORE upfront coordination, not less. Every interface between modules, every utility connection, every structural joint must be planned to millimetre precision.

The Fix:

The Trap: “We’ll inspect when modules arrive on-site.”

The Reality: Once modules are on-site, fixing defects requires partial disassembly of the modules. Catching issues in the factory saves weeks and lakhs.

The Fix:

Hindpride Standard: We invite clients for factory inspections at 25%, 50%, 75%, and 100% completion stages.

The Trap: “Building delivered. We’re done.”

The Reality: Like any building, modular structures need:

Get Your FREE Modular Construction Consultation

We’ll analyse your specific project and show you exactly how much time and money modular can save.

What You’ll Receive:

Zero pressure. Just data-driven insights from 18 years of experience.