Table of Contents

ToggleIf you are planning to build a farmhouse in Delhi-NCR, you are already navigating one of the slowest, most unpredictable construction ecosystems in India. Whether it’s in Chhatarpur, Asola, Gadaipur, Gurgaon’s Gwal Pahari, or Noida’s green belts, the story is always the same:

NCR is consistently ranked among the most delayed real estate zones in India, with thousands of stalled projects reported by RERA and national media (Hindustan Times, Times of India, ET Realty).

But here’s the reality most farmhouse buyers discover too late:

The brick-and-mortar method is the root cause of 80% of NCR’s construction delays.

Brick construction depends on:

When labour migration, climate change, pollution-driven shutdowns, and water scarcity hit NCR every year, traditional construction simply cannot keep up.

This is exactly why premium buyers, NRI investors, and sustainable developers are now shifting toward PCC panels in construction India — a technology that is finally making farmhouse construction:

And the most surprising part?

India’s own Ministry of Housing & Urban Affairs, GHTC-India, MoRTH, and IITs are aggressively promoting precast and prefab wall systems as the future of construction.

This blog breaks down exactly how PCC panels in construction India are rewriting the rules for NCR luxury farmhouses — with government data, IIT research, global engineering insights, real case studies, and deep technical analysis.

Let’s begin where the pain begins.

For premium farmhouse buyers in NCR, the dreams are big —

But the delays are bigger.

1.1 NCR Is India’s Delay Capital

Hindustan Times, Times of India, MoneyControl, and ET Realty routinely publish reports showing NCR as:

Why?

Because NCR faces a perfect storm of construction instability:

1.2 Why Brick Construction Cannot Cope

Brickwork is one of the most labour-intensive and climate-dependent methods in India.

Brick construction requires:

Which means your NCR farmhouse is vulnerable to:

This is why premium developers, including Hindpride, are replacing brick with PCC panels in construction India, which eliminate all these variables.

1.3 The Problem of Quality Inconsistency

India still builds homes like it’s 1980:

Two masons = two completely different walls.

Meanwhile…

PCC panels in construction India ensure factory-level consistency:

The contrast is monumental.

Before we explore the impact of PCC panels in construction India, let’s break down what they actually are.

2.1 Simple Explanation

PCC wall panels are:

Think of them as super-strong, perfectly finished concrete walls built like Lego blocks.

2.2 Types of PCC Panels Used in India

For NCR farmhouses, the most valuable are insulated sandwich PCC panels, which offer:

2.3 Why They Matter More in NCR Than Anywhere Else

NCR’s climate and geology make PCC panels more beneficial:

The Indian government actively promotes precast and prefab construction under:

BIS also has a standard for precast systems:

This proves that PCC panels in construction India are fully compliant, accepted, and encouraged by national policy.

PCC panels are not just a trend — they are part of a national engineering strategy.

3.1 MoHUA’s Technology Sub-Mission

MoHUA is clear:

“India must adopt sustainable, fast, innovative construction technologies.”

The mission promotes:

This is exactly the category PCC panels in construction India fall into.

3.2 GHTC-India — India’s Biggest Construction-Tech Revolution

The Government of India launched GHTC-India to adopt global construction technologies for India’s housing needs:

Under this project, government pilots across India demonstrate precast technology on a mass scale.

3.3 Lighthouse Projects (LHP Ranchi) — 1,008 Homes Built Using Precast

Precast technology was used to build 1,008 houses in Ranchi using factory-made volumetric units.

This is the strongest proof that precast is fully validated by the Indian government.

3.4 Road Ministry Mandates Precast for Highway Projects Above ₹300 Crore

The Ministry of Road Transport & Highways (MoRTH) has made it mandatory to use precast concrete elements in non-critical areas of all highway projects above ₹300 crore.

If national infrastructure is moving to precast, your private farmhouse should not be built with slow, outdated brick systems.

3.5 Market Data Shows India Is Shifting Hard Toward Precast

India’s precast concrete market:

PCC panels in construction India are part of this massive growth curve.

4.1 Parallel Processing Is the Key

Traditional method:

Step 1 → Step 2 → Step 3 → Step 4

Everything must be done in sequence.

With PCC panels in construction India, it becomes parallel:

Time saved = 30–40% instantly.

4.2 No Curing Time = Weeks Saved

Brickwork requires 7–14 days of curing.

PCC panels require 0 days.

For a 6,000 sq ft farmhouse → 20–40 days saved just from curing elimination.

4.3 Zero On-Site Wet Work Reduces Delays

Rain = brickwork collapses.

Fog = mortar doesn’t set.

Extreme heat = curing fails.

PCC panels are unaffected by weather because all critical processes happen indoors at factories.

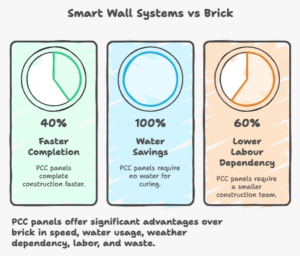

One of the most cited comparative studies shows:

Combine this with India’s climatic disadvantages → 40% timeline reduction is realistic.

4.5 BIS Standard Validates Speed & Reliability

India’s BIS Code for precast (IS 11447:1985) ensures:

This standard is the backbone of PCC panels in construction India.

5.1 NCR’s Water Crisis Makes Brick Construction Unsustainable

Curing brickwork requires:

NCR regularly faces water restrictions and tanker dependency.

PCC panels require NO curing water.

5.2 IIT Madras Research on Precast Sustainability

IIT Madras concludes:

5.3 Compatible With Next-Gen Geopolymer Concrete

IIT Indore developed a cement-free concrete with:

This aligns perfectly with PCC panels in construction India since precast factories can adopt new materials faster than on-site builders.

5.4 Zero Waste = Zero Mess

PCC panels eliminate:

Your farmhouse site remains clean, organised, and efficient.

NCR is one of India’s harshest climatic zones:

Brick cannot provide stable thermal performance.

But PCC panels in construction India offer:

6.1 Superior Thermal Results

Insulated sandwich PCC panels:

Perfect for:

6.2 Acoustic Performance

PCC panels provide:

This is why premium resorts and villas worldwide use precast walling systems — and why NCR farmhouse owners are adopting the same approach.

7.1 Upfront Cost: Slightly Higher

PCC panels may cost 5–10% more than traditional brick at first glance.

But the savings are hidden in:

7.2 Total Lifecycle Savings: 15–25%

Breakdown:

Total = ₹20–40 lakh savings for a premium farmhouse.

7.3 NCR Farmhouse Timeline Comparison

Brick Construction:

PCC Panel Construction:

For investors, time saved = faster rental returns + faster capital appreciation.

This is why developers increasingly use PCC panels in construction India to meet strict deadlines.

8.1 Quick Table

Attribute | Brick Construction | PCC Panels |

Timeline | 14–20 months | 8–12 months |

Wastage | 10–15% | <3% |

Water Use | Very high | Zero curing |

Quality | Variable | Factory-perfect |

Cracks | Frequent | Minimal |

Labour Dependence | High | Low |

Thermal Performance | Average | High |

Seismic Safety | Moderate | High |

Cost Predictability | Low | High |

Delays | Very likely | Very rare |

8.2 In-Depth Narrative

Brick construction is handmade, inconsistent, labour-intensive, and unpredictable.

PCC panels in construction India offer:

This is a no-brainer for NCR’s luxury farmhouse segment.

Project Specs

Results

Clients reported:

“This is the first home we built where we weren’t stressed about delays. The precision was unmatched.”

This is the future of premium living — and precisely why Hindpride champions PCC panels in construction India.

Brick belongs to the past.

NCR belongs to the future.

With water scarcity, labour volatility, rising heat, stricter pollution rules, and unpredictable weather patterns, traditional brick construction is no longer viable for premium farmhouse buyers.

Meanwhile:

PCC panels in construction India deliver:

NCR farmhouses built with smart wall systems are not just homes —

They are future-proof assets full of comfort, performance, and long-term value.

Q 1: What are PCC panels, and why are they becoming popular in India?

PCC (Precast Concrete) panels are factory-manufactured concrete wall systems produced in high-precision moulds under controlled curing conditions. Unlike brick walls, which are built layer-by-layer on-site, PCC panels arrive as completed structural elements ready for installation. This ensures uniform strength, crack resistance, perfect alignment, and zero curing delays.

The rise of PCC panels in construction India is driven by multiple national challenges:

With India adopting modern, faster, and greener construction technologies, PCC panels are now one of the most trusted wall systems for villas, farmhouses, and commercial spaces.

Q 2: Are PCC panels approved and recommended by the Indian government?

Yes. PCC panels are fully approved, recommended, and widely promoted by multiple Indian government bodies. They appear under MoHUA’s Technology Sub-Mission (PMAY-U) as a priority fast-track construction technology.

Additionally, GHTC-India (Global Housing Technology Challenge) has endorsed precast and used it in Lighthouse Projects (LHP) such as Ranchi’s 1,008 precast homes.

The National Highway Authority and Ministry of Road Transport & Highways have also mandated precast elements in major road projects.

These approvals make PCC panels in construction India a fully compliant, government-supported technology.

Q 3: How much faster is PCC panel construction compared to brick construction?

Construction using PCC panels is typically 30% to 40% faster than traditional brick construction. This acceleration happens because:

In regions like NCR—where monsoons, pollution bans, and extreme weather cause long delays—PCC panels in construction India can save 3 to 6 months for farmhouse projects.

Q 4: Are PCC panels stronger and more durable than brick walls?

Yes. PCC panels are significantly stronger because they’re cast in controlled factory settings with:

Brick masonry, on the other hand, depends heavily on mason skill, mortar quality, weather conditions, and curing consistency.

This is why PCC panels in construction India are preferred for durability, structural integrity, and long-term performance.

Q 5: Are PCC panels suitable for the extreme climate of Delhi-NCR?

Absolutely. NCR experiences 47–49°C summers, 2–3°C winters, 90% humidity monsoons, and frequent pollution bans. PCC panels perform exceptionally in such conditions because they offer:

This makes PCC panels in construction India ideal for premium farmhouses, wellness villas, meditation studios, and eco-friendly homes in NCR.

Q 6: What is the cost difference between PCC panels and brick construction?

PCC panels may appear 5–10% more expensive upfront, but they save significantly more in lifecycle costs, including:

Most NCR farmhouse projects end up saving ₹20–40 lakh when using PCC panels instead of brick.

This makes PCC panels in construction India financially smarter, not just structurally superior.

Q 7: Are PCC panels earthquake-resistant and safe for seismic zones?

Yes. NCR falls under Seismic Zone IV, where earthquake-resistant construction is mandatory. PCC panels excel here because:

In earthquake zones worldwide, precast is the preferred choice. Therefore, PCC panels in construction India enhance seismic safety for premium villas and farmhouses.

Q 8: Can PCC panels be customized for luxury farmhouse aesthetics?

100% yes. PCC panels offer incredible design flexibility:

Premium developers love PCC systems because they allow:

Luxury aesthetics are one of the reasons PCC panels in construction India are trending in farmhouse communities in Gurgaon, Chhatarpur, and Noida.

Q 9: Are PCC panels eco-friendly and sustainable?

Yes. PCC panels reduce environmental impact because:

In an era of rising environmental regulations, PCC panels in construction India are among the most eco-friendly walling solutions available.

Q 10: How do PCC panels help reduce delays in NCR farmhouse construction?

Farmhouse construction in NCR is often delayed due to:

PCC panels eliminate most of these hurdles:

By removing the top delay-causing factors, PCC panels in construction India help deliver farmhouses in 8–12 months instead of 14–20 months, making them perfect for NCR’s unpredictable conditions.

Build Your Green Farmhouse with Hindpride

Want a faster, greener, luxury-grade farmhouse with predictable timelines?

Let Hindpride build it with excellence.

Build smart. Build sustainable. Build with Hindpride.